|

| Finished Product |

|

| Make sure your clips are firmly attached to the bed! |

|

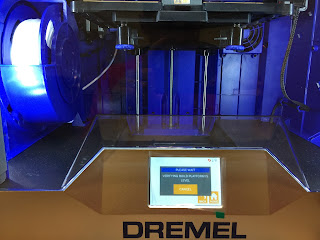

| Time Lapse of the Print |

Once the shirt was attached firmly to the bed without the clips being knocked off, it was smooth sailing. The print was rather fast, and the Dremel 3D40 did an excellent job printing as well as it would with a normal print bed. Looking back, I had the print probably a little too tall (the objects clink together), but it works well. The most surprising thing to me was that there was absolutely no melting of the shirt at all. The print is firmly attached to the shirt, but it can also be easily removed, which allows me to use the shirt again with other prints. I have also been surprised at how durable this is. I printed on this shirt 6 months ago, and the print is still firmly attached.

My students were very excited to see that I was printing on a shirt. The beauty of this project is it gave a lot of my students completely new ideas on things to attempt using a 3D Printer. This is a fun and easy project that you can attempt and be successful with. As long as you have your shirt attached securely, you will be ready to go.

For more information, check out this video: https://youtu.be/NlQCWMVCr4M